Method of installing and test for new nozzle of inkjet printer

1. In the trial before the nozzle, with a needle to test the nozzle to see if the plug. This is a very superfluous, and dangerous practice, first of all, once the nozzle into the water, you do not get dry on the machine power, ranging from burning board, while the head is burned; nozzle generally play a protective solution, you use the syringe into the head , Not only washed away the protection of the head of the liquid, and because the hand pressure is too large, likely to cause nozzle air block, resulting in no ink;

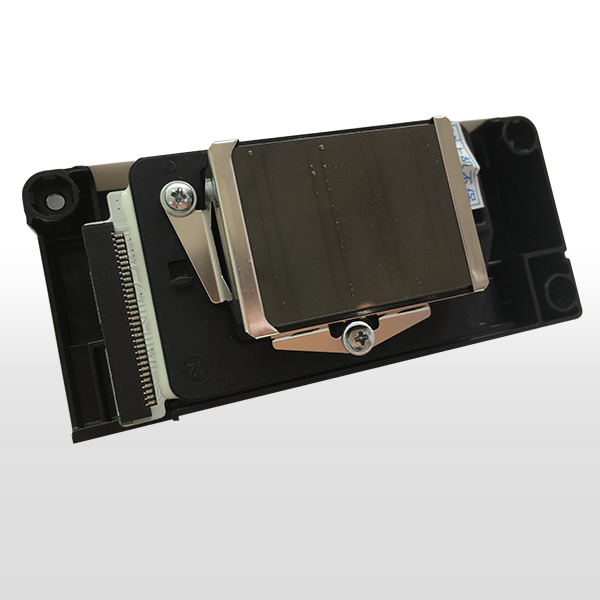

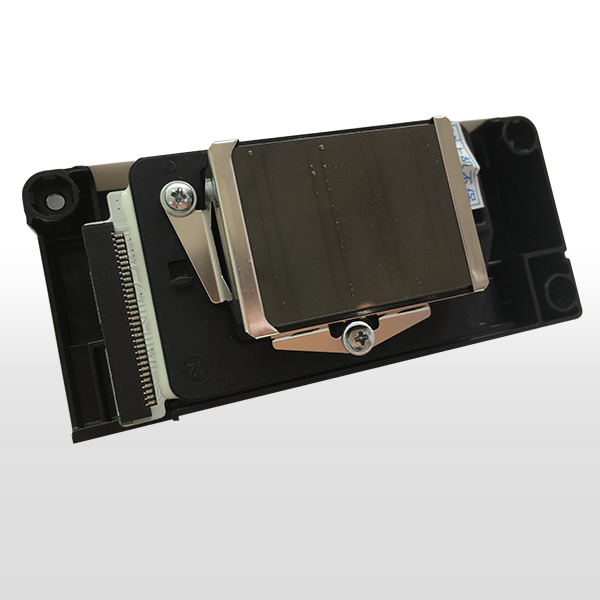

2. The head of the nozzle is very fragile, absolutely can not bump, do sure to protect. Its surface is a piece of aluminum, the inner layer coated with a crystal oscillator and very small ink tube. A touch will be concave, deformation, and even broken, so that the nozzle on the scrapped;

3. When installing the nozzle should also be careful, must first power, and installed in place. After the installation, the hand gently push the car around the move, check whether it is smooth, do not install the power on, because if the head is not in place, a car is easy to head to hit the broken, and the staff feel, , Controllable strong;

4. Plug the cable, do not bring the ink, but also to ensure good contact with the socket, do not touch the foot, otherwise, will cause the nozzle short circuit burned;

5. Steel shaft should be clean and smooth, paper towels can be used to wipe the sticky oil, do not directly to the shaft refueling, excess oil will flow to the nozzle up, causing damage;

6. Machinery, the circuit is correct, it is necessary to test the waterway, and first look at the amount of water within the cartridge enough; Second, check the small clean blade, suction pump is dirty;

7. Just installed inside the nozzle there will be air, so it will not immediately print the normal, only the head of the air completely discharged before the normal line out; specific steps are as follows:

First of all, can be used intermittent cleaning (cleaning only 2 times, and then stop after 30 minutes and then wash 2 times) repeatedly washed too much, will cause the cleaning pump ink, not only will print color, ink leakage, but also a waste of ink.

Second, you can print more pictures, so that the nozzle in the work of put the air out;

Once again, if the machine has been led to the waste ink tube, you can first power, and then set a rubber tube with a rubber tube to suck the waste ink tube until the extraction of 3-5ML ink so far, and then boot, with the machine normal cleaning time, Artificially to the head of the air to the hard out, the side effect is likely to cause cleaning pump heap.

You may like that: Shocked the occupation of 1.3 billion people